Industrial brakes are essential components for machinery, responsible for stopping or holding a load safely and efficiently. While there are many types of brakes, two of the most common are electromagnetic and hydraulic. Understanding the fundamental differences between these two systems is crucial for selecting the right brake for a specific application.

How Do They Work

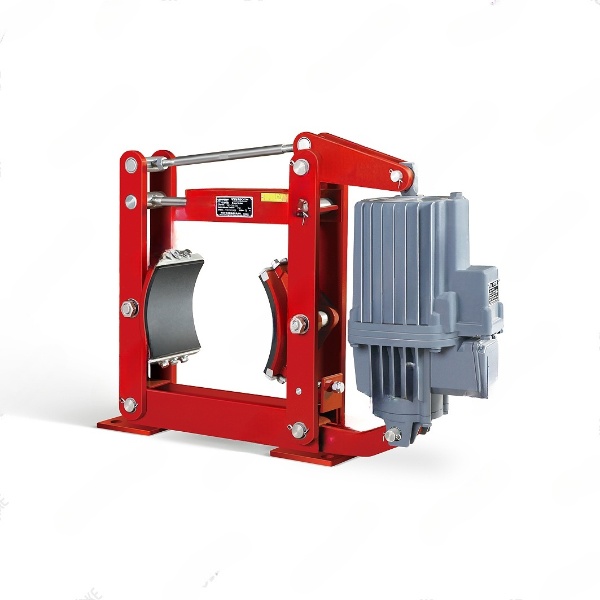

Electromagnetic brakes operate using a simple but effective principle: electromagnetism. When an electric current is applied, it generates a magnetic field that attracts a friction plate, stopping the rotating component. When the power is removed, the magnetic field disappears, and the brake is released. There are two main types: power-on brakes (energize to brake) and power-off brakes (energize to release), with the latter being more common for safety-critical applications like elevators and cranes.

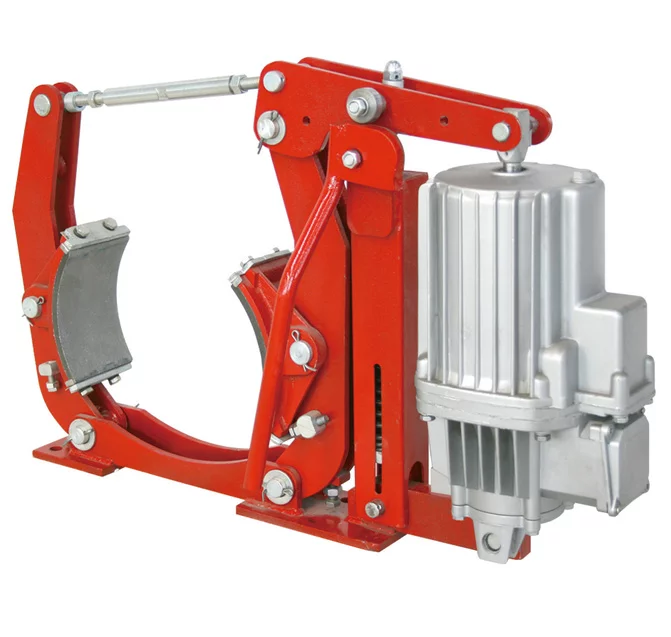

Hydraulic brakes, on the other hand, rely on fluid pressure to create braking force. A hydraulic pump pressurizes a fluid (usually oil), which is then directed to a cylinder. The pressure in the cylinder pushes against a piston, which in turn presses friction pads against a rotating disc or drum. To release the brake, the fluid pressure is relieved.

Electromagnetic Brakes Advantage:

- Fast Response Time: They engage and disengage almost instantly, making them ideal for applications that require quick, precise stopping.

- Simple Installation and Control: The system is relatively straightforward, requiring only an electrical connection. This simplifies installation and allows for easy integration into electronic control systems.

- Dry Operation: They don’t use any fluids, which eliminates the risk of leaks and reduces maintenance requirements.

- Compact Size: Electromagnetic brakes are often more compact than their hydraulic counterparts, making them suitable for machines with limited space.

Hydraulic Brakes Advantage:

- High Braking Force: Hydraulic systems can generate a massive amount of force, making them the preferred choice for heavy-duty applications that involve large loads and high speeds, such as in large cranes or rolling mills.

- Smooth and Consistent Braking: The force can be precisely controlled, providing a very smooth and consistent braking action.

- Durability and Reliability: The robust nature of hydraulic systems allows them to withstand harsh industrial environments.