Industrial brakes are essential safety and control devices used in machinery across virtually every industry, from cranes and conveyors to wind turbines and elevators. Their primary function is to slow down or hold a moving load or rotational component by converting kinetic energy into heat.

The core principle behind most industrial brakes is friction. A force is applied to press stationary friction material, like brake pads or linings, against a rotating part, such as a disc or drum. This contact creates frictional resistance, which opposes the motion and generates a braking torque.

Key Components and Operation

- Actuation Mechanism: This is how the braking force is initiated. Common methods include:

- Electrically Actuated (Electromagnetic): An electromagnet applies or releases the brake. These are very common for holding applications (fail-safe brakes).

- Hydraulically/Pneumatically Actuated: Fluid or air pressure pushes the brake pads into contact. These often provide high stopping power.

- Spring-Applied: Springs are used to apply the braking force, and an external power source (electric, hydraulic) is used to release it. These are the most common fail-safe systems, ensuring the brake engages if power is lost.

- Friction Material: High-durability materials (like organic, semi-metallic, or ceramic compounds) that are designed to withstand high temperatures and wear over time.

- Braking Element (Disc or Drum): The rotating component that the friction material acts upon.

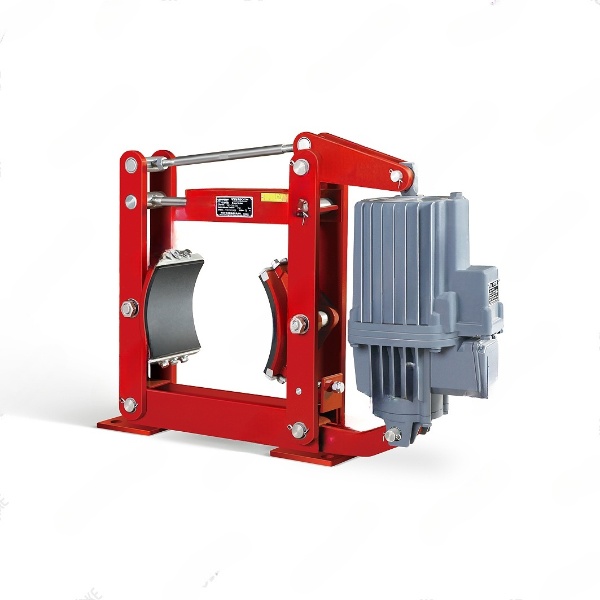

Types of Industrial Brakes

While the friction principle is common, industrial brakes are categorized by their design:

- Disc Brakes: Use calipers to squeeze pads against a rotating disc (rotor). Known for excellent heat dissipation and consistent performance.

- Drum Brakes: Use shoes that push outwards against the inside surface of a rotating drum. Often used where high braking torque is needed in a compact space.

- Caliper Brakes: A broad term, often referring to brakes where a caliper mechanism clamps down on a disc, particularly heavy-duty ones.

- Electromagnetic Brakes: Use magnetic force to engage the brake directly, often functioning as clutches or holding brakes in precision machinery.

If you need high quality industrial brakes, please feel free to contact COCONET Brakes via WhatsApp +86 18518569415