In the industrial sector, reliable and precise braking systems are non-negotiable for safety, control, and operational efficiency. The choice often narrows down to two principal technologies: electromagnetic brakes (EM brakes) and hydraulic brakes. While both are designed to slow down or hold industrial loads, their operating mechanisms, performance characteristics, and ideal applications differ significantly.

1. Principle of Operation and Force Transmission

| Feature | Electromagnetic Brakes (EM) | Hydraulic Brakes |

| Working Principle | Utilizes an electromagnet to create a magnetic field that attracts an armature, generating friction against a stationary plate. | Relies on fluid pressure (Pascal’s Law) generated by a pump or cylinder to force brake pads/shoes onto a rotor/drum. |

| Force Medium | Electricity (to create the magnetic field) and Friction. | Incompressible Fluid (Brake Fluid or Oil) and Friction. |

| Actuation | Direct electrical signal via a solenoid/coil. Ideal for automated and remote control. | Fluid power generated by a hydraulic pump (often motor-driven in industrial settings). |

2. Performance and Control

Electromagnetic Brakes are highly favored for applications requiring speed and accuracy:

- Response Time: Extremely fast due to the near-instantaneous build-up and collapse of the magnetic field. This makes them excellent for quick stops or emergency braking.

- Control: Offers highly precise and smooth torque control by simply modulating the electrical current supplied. They are ideal for tensioning systems, positioning, and smooth motor stops (e.g., robotics, packaging).

- Fail-Safe Design: Most industrial EM brakes are “spring-applied, power-off” (SAFETM). They are held off by power and engage automatically when power is lost, making them critical safety/holding brakes for elevators, hoists, and servo motors.

Hydraulic Brakes are primarily chosen for brute force and heavy-duty use:

- Braking Force: Capable of generating immense, sustained braking force in a compact size, making them the superior choice for extremely heavy loads and high-stress applications.

- Heat Dissipation: Hydraulic fluid systems and larger caliper designs are generally very effective at dissipating heat, allowing for prolonged, continuous, or high-frequency braking cycles without significant fade.

- Smoothness (Heavy Loads): The gradual buildup of fluid pressure often results in a smoother, more controlled deceleration of very heavy loads (e.g., large overhead cranes, rolling mills), minimizing load shock.

3. Maintenance, Safety, and Environment

| Feature | Electromagnetic Brakes | Hydraulic Brakes |

| Maintenance | Lower complexity. No fluid to manage. Main wear is on the friction faces and occasional coil check. | Higher complexity. Requires regular checks for fluid leaks, contamination, and degradation (which can lead to corrosion and brake fade). |

| Cleanliness | Clean. No risk of fluid leakage, ideal for food processing, pharmaceutical, and clean-room environments. | Potential for leaks. Requires a Hydraulic Power Unit (HPU) and associated plumbing, posing a risk of oil contamination in sensitive areas. |

| Environmental | Generally quieter (especially at idle) and better suited for the electrification trend in industrial machinery. | Can be noisier due to the pump and can suffer performance issues in extreme temperature variations. |

| Lifespan | Can have a shorter lifespan under continuous, heavy-duty cycling due to wear on the direct-contact friction components. | Tends to have a longer service life in heavy-duty applications, provided the fluid and seals are maintained properly. |

Conclusion

The distinction between the two in the industrial environment is clear:

- Choose Electromagnetic Brakes for applications requiring high speed, precise positioning, quick emergency stops, and minimal maintenance (e.g., conveyor belts, robotics, automated guided vehicles, parking brakes).

- Choose Hydraulic Brakes for applications demanding maximum braking force, continuous high-stress operation, and effective heat management (e.g., large overhead cranes, heavy-duty mining equipment, metal forming machinery).

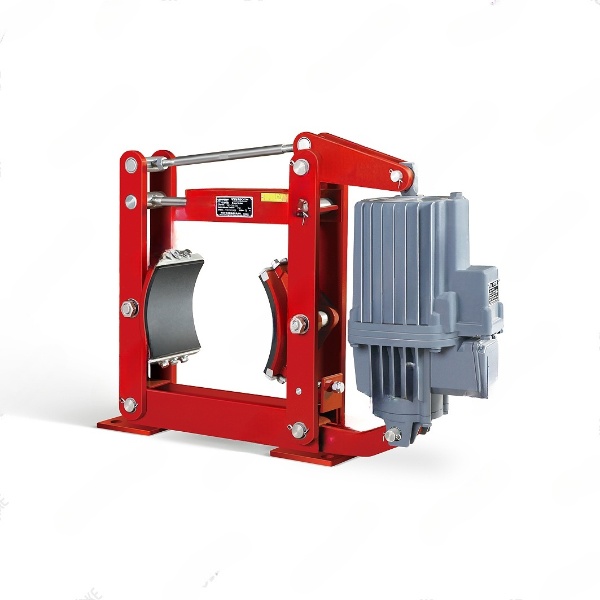

In some high-demand systems, electro-hydraulic brakes are used, combining an electric motor to power the hydraulic actuator, offering the high force of hydraulics with the precise electrical control of a solenoid.